|

NATIONAL MUNITIONS

COMPANY

Eldred Building No 12: Bomb Shell Loading |

|

|

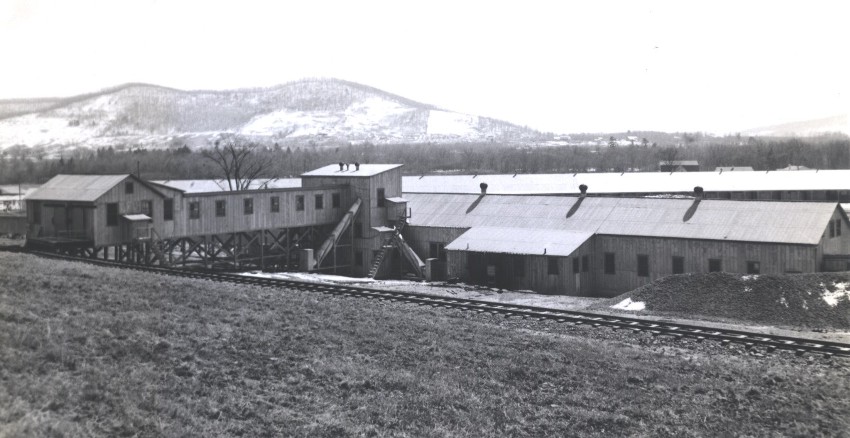

View of east elevation

of the Shell Loading Buildings. The building at the left, No 15,

is the Receiving and Screening building for Ammonium Nitrate and

TNT. The nitrate is brough down from the storage building No 8

and the TNT from the storage magazine by narrow gauge rail. The

covered passageway connects with the third story of Building No

15, the Amatol mixing house.

|

|

|

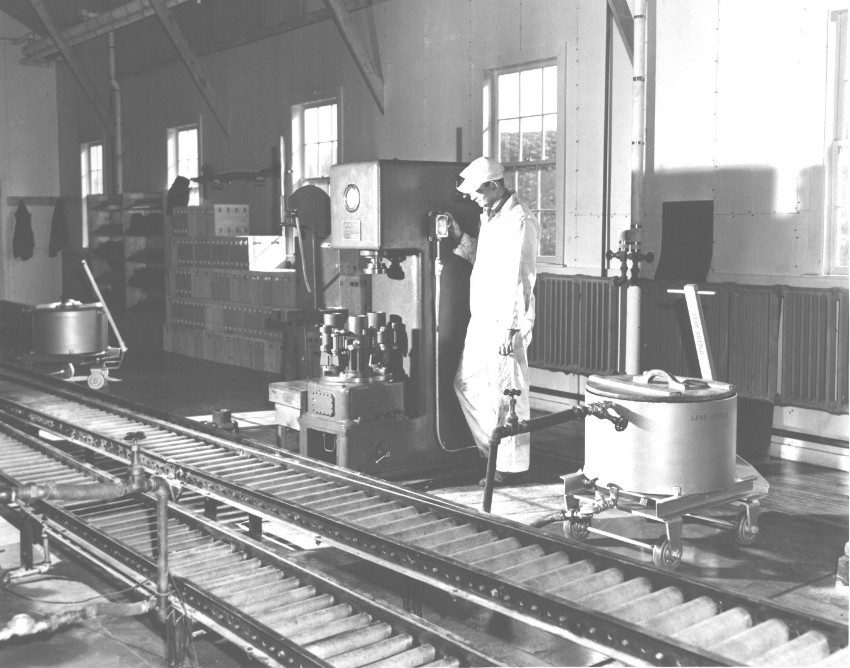

Interior view of Shell

Loading Building No 12, looking east toward the conveyor entrance

from building 10.

Notice the large Denison hydraulic presses toward the rear and also the roller conveyor system. Empty bomb trays roll down the upper conveyor by gravity to be used again. |

|

PREHEATING

ROOM

|

|

At the end of the conveyor

passageway before entering building 12, the bombs enter a heated

room to bring their temperature up to a point suitable for loading.

This view is through the pre-heater looking toward the entrance

to the loading building 12.

|

|

|

View showing Amatol

buggy with steam line connected to keep the Amatol warm while

being loaded into the bombs.

The bombs are loaded in two increments. |

|

|

Detailed view of Denison

Hydraulic indexing press, for pressing Amatol to proper density

in the bomb shell. Note the bomb holders or chucks on the press.

These are so designed that the pressure of the press is exerted

on the walls of the bombs and not on the tail.

|

|

|

Another detailed view

of the Denison Hydraulic press in action.

|

|

|

View showing bombs

being placed in bomb holder for pressing the Amatol in the bomb

body to the proper density. In pressing the second increment of

Amatol into the bomb, the cavity to receive cup, adapter and fuse

is formed simultaneously. The wax cup, into which the booster

or adapter is placed, is then inserted and sealed with TNT.

|

|

|

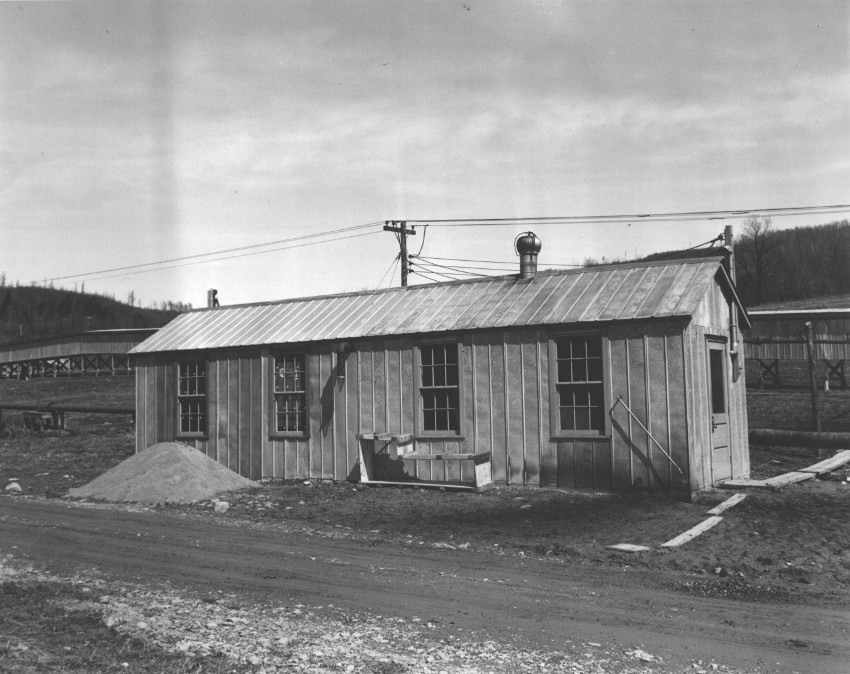

Compressor House

This building housed the air compressors which furnished compressed air for the operation of the shell loading equipment. It was located outside the barricade adjacent to Building No 12. |